- Home

- /

- Industrial automation

- /

- Automation systems

- /

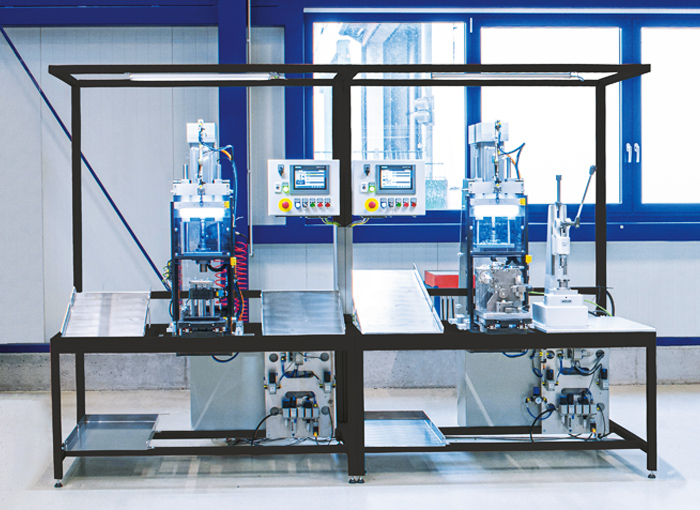

- Partially automated manual workstations

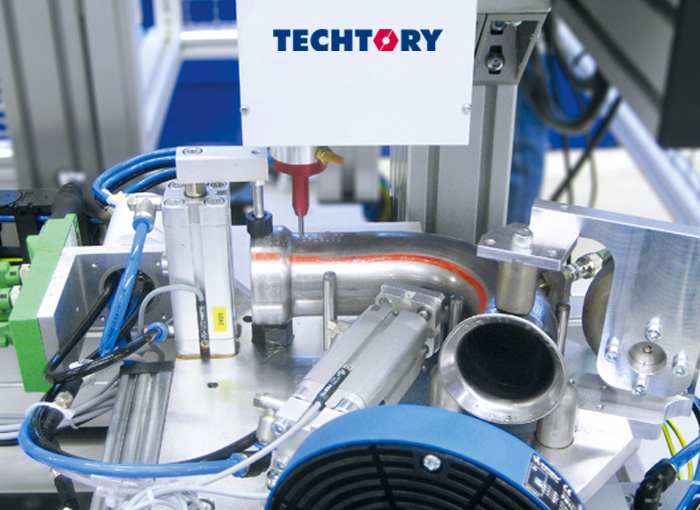

Automation and cutting technology

TECHTORY Automation GmbH

Ludwig-Winter-Straße 5

77767 Appenweier

| Phone | +49 7805 9589-0 |

| Fax: | +49 7805 9589-50 |

| Email: | info@techtory.de |