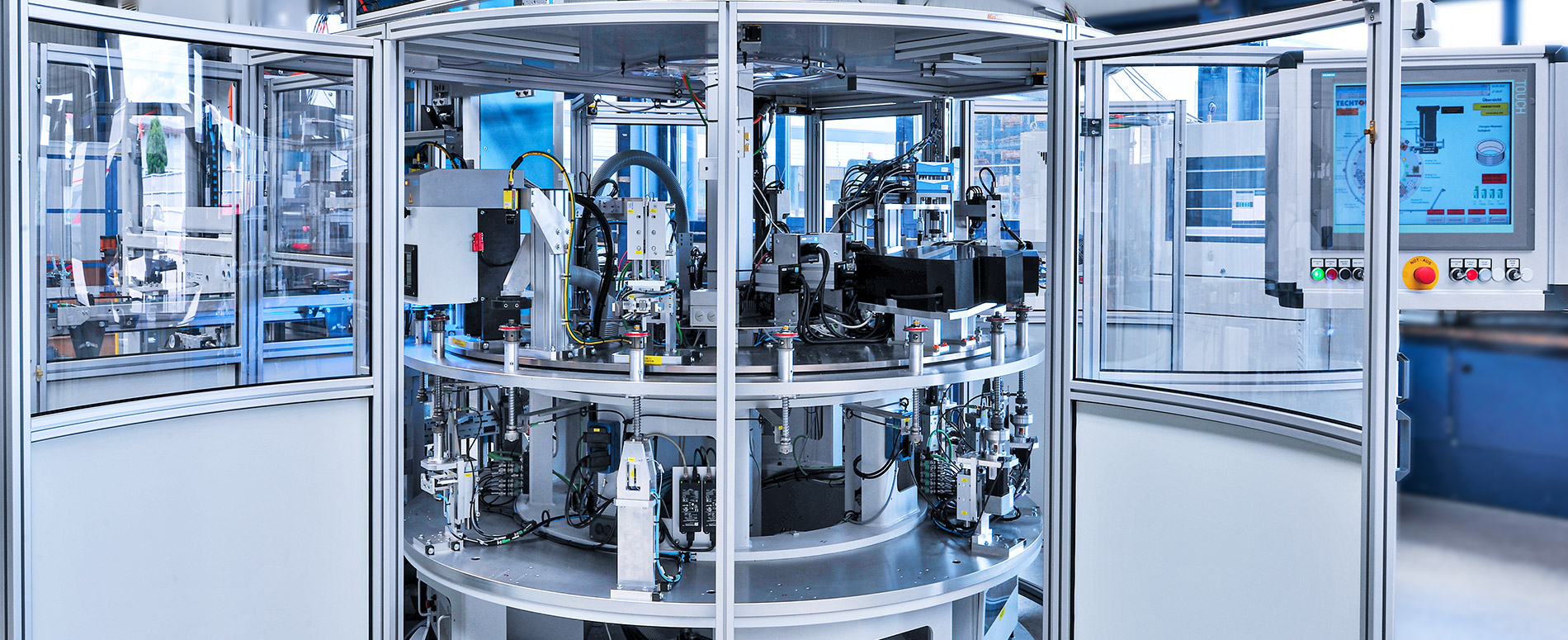

Quality assurance during development and production is an important criterion in series production.

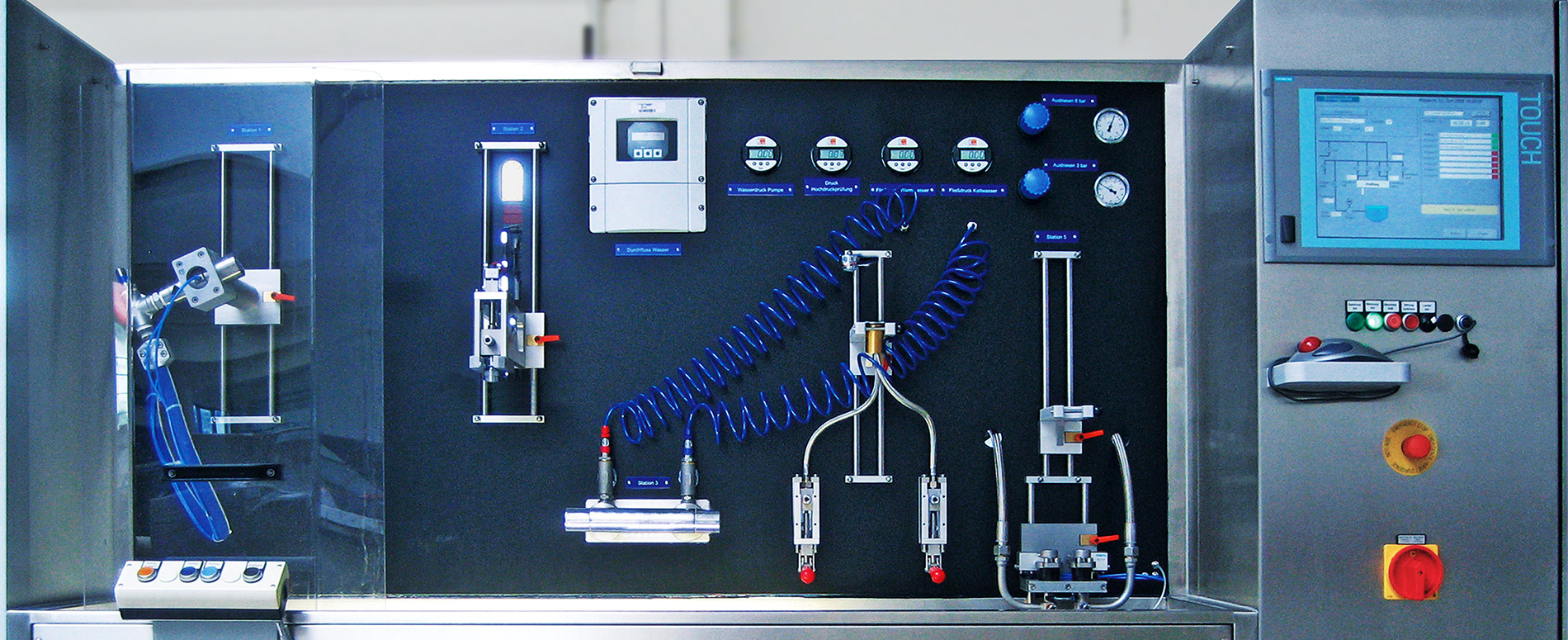

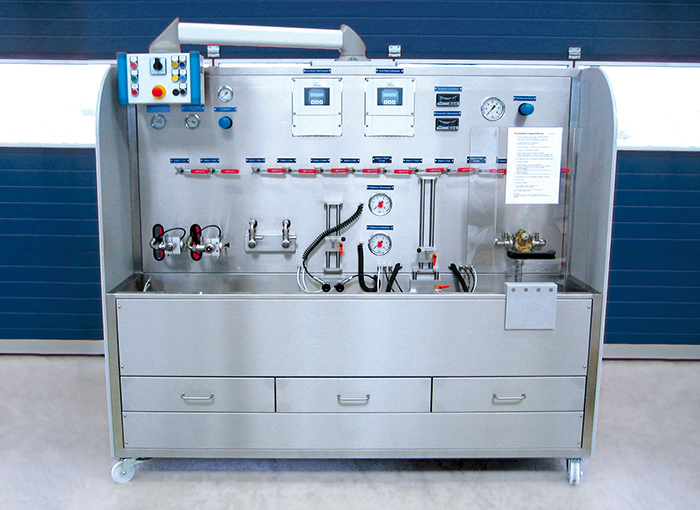

All our experience in measurement technology, electrical engineering, computer science and process engineering goes into the development and construction of individual test benches.

The test sequences are individually adapted to your needs and products. Product-specific adapters allow the fittings to be connected to the various test stations and enable the test benches to be used independently of the product.