- Home

- /

- Products

- /

- cell-systems

- /

- TECHTORY-floor-cell

Automation and cutting technology

TECHTORY Automation GmbH

Ludwig-Winter-Straße 5

77767 Appenweier

| Phone | +49 7805 9589-0 |

| Fax: | +49 7805 9589-50 |

| Email: | info@techtory.de |

Plan and configure your automation project with professional 3D models from our automation toolbox.

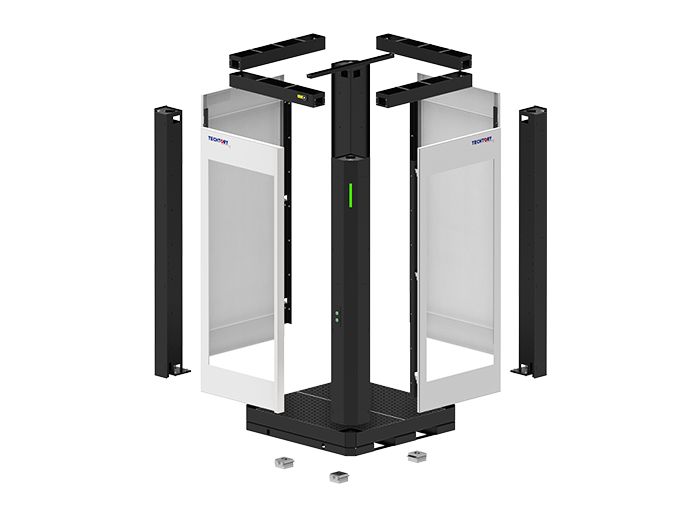

| 1 | Lighting module | |

| 2 | Column with integrated status light | |

| 3 | Floor assembly with grating | |

| 4 | Filling with captive screws | |

| 5 | Carrier door | |

| 6 | Carrier filling | |

| 7 | Door | |

| 8 | Precision machine shoes | |

Lighting module

Column with integrated status light

Floor assembly with grating

Filling with captive screws

Carrier door

Carrier filling

Door

Precision machine shoes

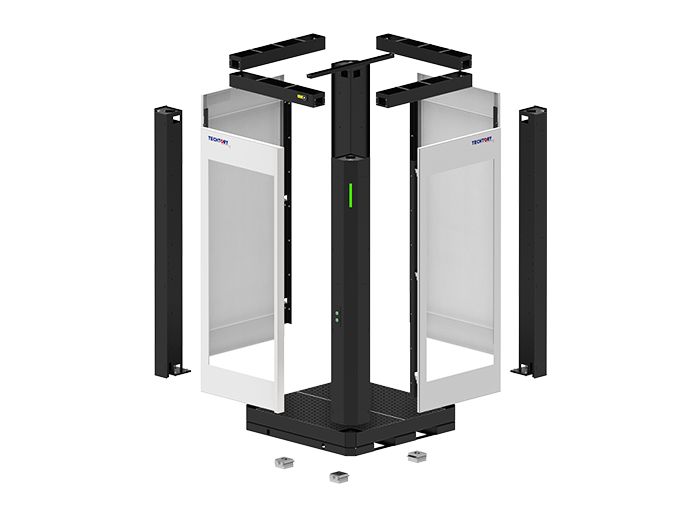

| 1 | Lighting module | |

| 2 | Column with integrated status light | |

| 3 | Floor assembly with grating | |

| 4 | Filling with captive screws | |

| 5 | Carrier door | |

| 6 | Carrier filling | |

| 7 | Door | |

| 8 | Precision machine shoes | |

Lighting module

Column with integrated status light

Floor assembly with grating

Filling with captive screws

Carrier door

Carrier filling

Door

Precision machine shoes

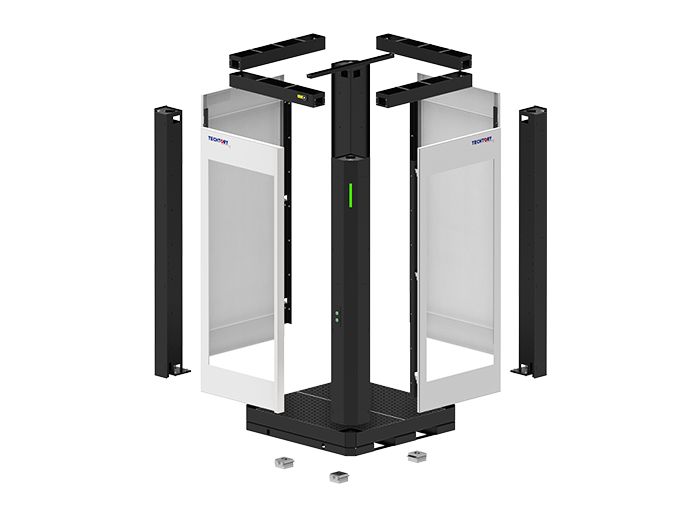

Lighting module

Column with integrated status light

Floor assembly with grating

Filling with captive screws

Carrier door

Carrier filling

Door

Precision machine shoes

| Length (A) | 1.422 mm |

| Usable length (A1) | 1.000 mm |

| Width (B) | 1.452 mm |

| Usable width (B1) | 1.000 mm |

| Height (C) | 2.389 mm |

| Weight | 800 kg |

| Length (A) | 1.422 mm |

| Usable length (A1) | 1.000 mm |

| Width (B) | 1.452 mm |

| Usable width (B1) | 1.000 mm |

| Height (C) | 2.389 mm |

| Weight | 800 kg |

Configure your individual floor-cell system from selected, standardized modules

The unique configurability of the TECHTORY-floor-cell results in a wide range of possibilities.

Stringing together multiple individual cells through the use of center columns. By installing additional corner variants (e.g. inside corners), combinations with offsets are also possible.

The block cell is an extension of the row cell in terms of depth by using center columns in the second level.

By using separable corner or center columns, the cell variants can be separated for transport.

This results in optimal utilization of the truck and facilitates internal transport. In the process, all components remain in their assembly location, which enables faster recommissioning during reassembly.

Arrangement of components by using inside corner columns to form a U or L arrangement.

Especially for these variants, the separable columns are of great importance, for the relocation to the place of use.

Automation and cutting technology

TECHTORY Automation GmbH

Ludwig-Winter-Straße 5

77767 Appenweier

| Phone | +49 7805 9589-0 |

| Fax: | +49 7805 9589-50 |

| Email: | info@techtory.de |